De-Farbing the BAR: Bipods

Date Written: February 2009

Author: Chris Guska

Archival Support: George Knott

One of the top 3 dubious components used by WWII Reenactors on their Browning Automatic Rifles is the Bipod Assembly. This is universally applicable to all WWII Reenactors, ETO, MTO and PTO alike.

There are 3 types of Bipod Heads and 2 types of Bipod Legs, some of which are universally correct for WW2 use, while others use is incorrect or limited at best.

The Bipod Assembly, Part 7312239:

The bipod assembly consists of 9 parts

1.) The bipod head B-147337 / 6147337

2.) Inner Leg B-147333 / B-7312236-1 and B-7312237-1

3.) Outer Leg B-147340, B-147341 / 5152775

4.) Leg Keys (2) 7312238

5.) Thumbscrews (4) #152774

There are variations and construction differences in the bipod head, inner leg, outer leg, and thumbscrews in wartime and postwar examples.

Bipod Heads:

There are three types of Bipod Heads that were produced for the M1918a2.

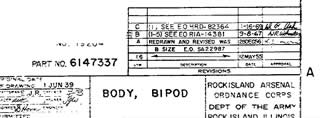

1.) Forged - Part # 6147337

2.) Cast - Part # B-147337

3.) Cast / Stamped 614337

1.) Forged 6147337This type of bipod head is the least commonly seen in use by shooters and reenactors. This bipod head can be identified by a horizontal seam that divides the front and rear halves of the bipod head. The features of this bipod head are slightly "thicker" than that of the later cast heads. This type of bipod head is rounded across the bottom of the head, without the distinctive channel / bump seen on the cast types.

The Forged type bipod head was developed in 1939 as a part of the modernization and A2 programs for the 1918 BAR. This type was in production from 1941 to 1943 and was utilized interchangeably with all other types of bipod heads till the BAR was withdrawn from service.

This type of head is appropriate for all ETO and the majority of PTO impressions.

Of note with this part number is that there are two variations, both bearing the same part number. The second type closely resembles the arm contour of the cast types. The outside portion of the clamp arm is noticeably thinner. The "thinner" type does not appear to marks from machining evident on the thinner portion of the head, it appears to have been forged this way.

2.) Cast B-147337

This type of bipod head is also seldom seen in use by shooters and reenactors. This bipod head can be identified by a seam that divides the right and left halves of the bipod head, with a distinctive channel on the bottom of the head with a flat milled in it.

The Cast type bipod head was introduced in 1942 as a production variance and simplification for mass production by IBM and NESA contractors. This type was in production from 1942 through the end of BAR production by Royal Typewriter during the Korean War. The Cast type was utilized interchangeably with all other types of bipod heads till the BAR was withdrawn from service.

This type of head is appropriate for all ETO and the majority of PTO impressions.

3.) Cast / Stamped, 6147337 (1955)

This is the most common type seen in use by shooters and reenactors. This bipod head can be identified by a 2nd piece of flat steel attached to a machined lower casting.

On Oct 15 1942 a committee was formed to review possible changes to the BAR that would facilitate improved manufacturing efficiency and one of the recommendations the committee approved was the 2 piece bipod head. One of the other recommendations was to transition to a Cast type head. Unfortunately the committee heard recommendations for the duration of the war and records don't exist as to when any of the specific recommendations were heard by the committee. The definitive dated records to state when the cast head and stamped heads were "approved" are unavailable or simply don't exist, so we must examine original examples and documented wartime photographs.This type was introduced, approved and produced during the war by NESA as an improvement to the cast heads, solving the inherent weakness of the thin outside clamp leaf that was prone to breakage. A single piece of stamped steel was utilized on top of a lower casting, greatly improving the strength of the leg clamp, reducing breakage and simplifying production. The lower portion could be cast and finish machined at a lower cost than the earlier cast type because of the stamped top strap. This type was in production from the end of WW2 till BAR and accessory procurement ceased, being utilized interchangeably with all other types of bipod heads till the BAR was withdrawn from service.

Previously this version was thought to have been only produced post WW2, as evidenced by the earliest drawing that the variation appears in dated 1955.

Only after the discovery of a NE-6 marked 2 piece bipod head did we re-examine the issue and find reference to the recommendation by the committee for a 2 piece head.

As of the date of this article, I have yet to find a captioned or dated wartime photo that conclusively demonstrates that the 2 piece stamped bipod head saw any combat usage during WW2. If this variant did see usage, it would be in the extreme minority to the cast and forged types. This type of bipod should be looked at in the same way as bayonet lugs on the M1 Carbine - yes, they were a wartime variant, but it remains inconclusive if any saw combat service during WW2.

This type of bipod head is appropriate for Korean and Vietnam War impressions. I can not recommend this type for "common" use for WW2 Impressions.

Bipod Legs:

There are three pieces to the legs, since they all go together, they will be addressed together. The legs consist of an inner leg, an outer leg and an alignment key that keeps the outer leg from spinning on the inner leg.

There are two basic types of leg assemblies - for our purpose we'll refer to them as Early and Late.

1.) EarlyThe "Early" leg assembly consisted of a lower leg with foot that telescoped INSIDE the upper leg which had a thumbscrew clamp at the bottom (distal of the head). There was a separate (different) upper leg for the right and left side. The part numbers were B-147340 and B-147341 for the right and left leg respectively.

Detail of the part numbers, in comparison to the single part number late leg type

Wartime Upper legs were frequently marked with the maker mark - in this case (NE5)

The lower leg assembly was slotted for a key which maintained the alignment of the lower leg to the upper leg and head. This key way is only cut on one side of the lower leg.

Detail of the lower leg, Part B-147333, showing the part number and key way

The key also acts as a limiting stop so the lower leg can not drop out of the upper leg.

Detail of (NE1) marked bipod key

This leg assembly was in production from 1941 till 1944

This type of leg is appropriate for all ETO and all PTO impressions.

2.) Late

The "Late" leg assembly consisted of a lower leg with foot that telescoped OVER the upper leg, with a thumbscrew clamp at the top of the lower leg assembly (proximal to the head).

Detail of the lower legs, showing part numbers B-7312236-1 and B-7312237-1 for the right and left legs respectively.

The upper leg assembly was slotted for a key which maintained the alignment of the lower leg to the upper leg and head. This key way was cut on BOTH sides of the leg so that the part could be used interchangeably for the right and left sides. The key also acts as a limiting stop so the lower leg can not slide off of the upper leg. The part number for the later universal leg is 5152775

Ordnance Committee Minute number 23850, dated May 18, 1944 called for the Modification of bipod assemblies for the M1918a2 BAR to permit easier adjustment of the legs

This leg assembly was in production from summer of 1944 and issued till the BAR was withdrawn from service.

This type of leg is only appropriate for Late WWII (1945) ETO and PTO impressions.

Thumbscrews, 152774:

There are several types of thumbscrews seen on BAR Bipods. There is a "small" and a "large" type, where both types had the same thread size and pitch, but the "ears" of the thumbscrew were significantly larger or smaller than the other type. Most commonly found are 5/16th 24 threads per inch thumbscrews - while some early BAR's used 1/4 - 20 type thumbscrews.

Bipod Assemblies, Usage & Conclusion:

So now you've seen that there are three types of heads and two types of leg assemblies, with only some of those combinations correct for use for WWII reenacting.

Here are some of the combinations which are acceptable for use as "factory produced":

1.) Forged Head, Bottom Screw

2.) Cast Head, Bottom Screw

3.) Cast Head, Top Screw (1945 Impressions Only)

The following are unacceptable for use for WWII reenacting:

1.) Stamped Head (doesn't matter what type of leg since the stamped head is just wrong)

Usage & Conclusion

All of this talk of bipods raises the question- "How often were bipods really used?"

I hope to follow up to this article with a photo study of ETO usage of the BAR to identify trends in bipod usage, bipod types, parts usage as well as field gear and BAR Impressions.

From the dozens of photos I have examined over, bipod usage is mixed - with the bipod and even the flash hider being discarded by many gunners to save weight.

Remember: "Less is More" - that if you happen to have a late style bipod, it is certainly correct to leave it at home and go without until the time comes when you can find and afford to purchase a correct bipod head or complete assembly appropriate for your focused impression.

Sources:

Ballou, James L. Rock in a Hard Place, The Browning Automatic Rifle. Collector Grade Publications, 2000.

Foster, Sean. "BAR Bipods." Phone interview. 22 Feb. 2009

Knott, George. "BAR Bipods." Phone interview. 9 Mar. 2009

Knott, George. "BAR Bipods." Email Correspondence. 26 Mar. 2009

"LIFE Image Archive powered by Google." LIFE Magazine Winter 2008.

90th IDPG Articles