IMPORTANT:

Proceed at your own risk. We're not responsible for you blowing yourself or your gun up.Blanksguy’s M1911 Pistol .45ACP Blank Information

Written by Richard S (Blanksguy)

Content last updated: August 4, 2002

Digitized and Published by the 90th IDPG: January, 2008

Procedure

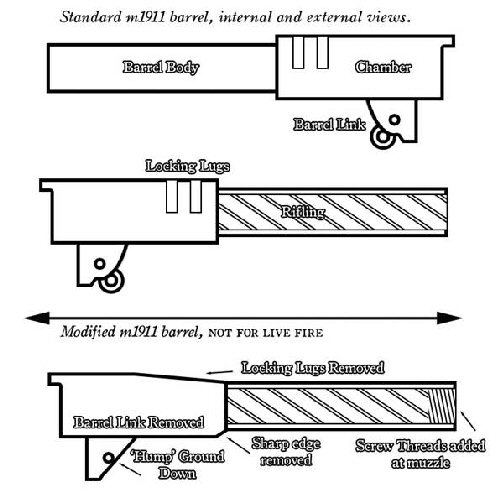

1.) Grind or Machine off the locking grooves

2.) Thread inside of barrel with ½ x 20 Tap, and check the outside of the barrel for bulges from tapping

Note: the outside of the barrel should have .005” to .010” clearance in the barrel bushing. Remove metal from the outside of the barrel with emory-cloth to achieve clearance.

Notes:

1.) When grinding away Locking Grooves, remember that the metal is thin in this “Chamber” area. Smooth the ground area with emery cloth.

2.) Some .45 ACP M1911 Pistols work better with the locking-link; so you will have to try both ways. USE ONLY PISTOL BLANKS!

3.) Make up different size BFA “plugs”:

IF YOU ARE USING JOE SWANSON'S BLANKS - THESE SIZES ARE MUCH TOO SMALL. CONTACT JOE SWANSON FOR THE CORRECT SIZE DRILL BITS.

.180” #15 Drill

.170” #18 Drill

.159” #21 Drill

.150” #25 Drill (.152” hole)

.140” #28 Drill

.129” #30 DrillStart with the largest size hole and work down, stopping when the gun works. Make the BFA Plugs from ½ x20 Allen set screws, center drilled to above required sizes.

4.) Remember, this is a BLANK FIRING ONLY BARREL. You can’t use it for live firing! DO NOT USE SUBMACHINEGUN BLANKS IN PISTOLS!

90th IDPG Projects