Foreword:

I've built a few Browning 30's in the past few years. I've generally stuck with one manufacturer of semi auto sideplates, but due to an extended delay with my primary supplier, I decided to take a chance on something different.

Building a 1919 from a parts kit and stripped semi plate is not something I'd recommend for the novice hobbyist, but for those of us a reasonably well equipped shop and courage - it is very achievable to get good results. Its a gratifying process, that gives you an intimate knowledge of how these guns work. Additionally, this gives you the opportunity to hand select parts, and build the gun as correctly as possible to recreate the appearance of a "factory correct" wartime production gun. This includes the "replica" engraving on the new semi auto sideplates that recreate the original style markings.

Here are my observations from what showed up.

Overview:

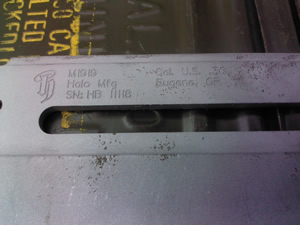

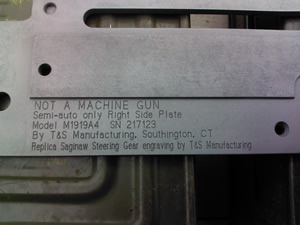

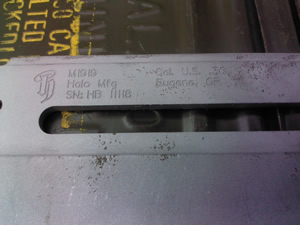

I purchased semi auto, "100%" completed sideplates from T&S Manufacturing of Southington CT, and from Halo Manufacturing of Eugene, Oregon.

Both T&S and Halo offer semi auto sideplates with replica 1919A4, 1919A6, 1917A1, and 1917 engraving.

These items are regulated as Title 1 firearms, and must be received / transferred by a FFL, much as you would with any other Rifle, Shotgun or Pistol.

Cost:

T&S - $250 per plate + shipping (usually $15~)

Halo - $180 per plate + shipping ($18)

Delivery:

T&S - I've bought from T&S a couple of times. The first time the turn around was a matter of weeks. The second time was a rather long wait due to some unforeseen circumstances @ T&S. At this time, I believe things have been worked out and plates are generally in stock and ready to ship. Communications can be spotty, with some delays in responses via email for days, even sometimes weeks. I've never been able to get ahold of T&S on the phone.

Halo - Quick turn around time, but no communications. I reserved a plate online through the Halo web site, sent in payment via mail, as credit cards are not accepted online, then heard nothing. No confirmation that payment was received, no confirmation or tracking number that the order had shipped. Additionally, the FFL to which I had the side plate shipped to didn't bother to call me and let me know when the plate arrived.

Side by Side Comparisons:

I'll let most of the photos do the talking here, with some notes interspersed.

| Halo |

T&S |

|

|

Side by side view. From this vantage point, some of the differences start to become visible.

It is obvious that the Halo plate is missing holes. The bottom plate rivet holes have not been drilled, let alone "spot drilled" on the inside of the plate. It is missing the right front cartridge stop hole.

The T&S plate has all the holes it should, as per the print. The right rear cartridge stop hole has been threaded and skim welded over and ground flush so that screws can be used, providing the ability to swap between a 308 and 30.06 rear cartridge stop. This is a very nice option, and a huge plus for the reenactor.

From the manufacturer, the T&S plate comes sandblasted on both faces. The outside of the T&S plate was blanchard ground prior to media blast. The Halo plate is bright, not media blasted on the outside face - exhibiting a blanchard ground surface. The inside of the Halo plate has been sandblasted.

|

|

|

Inside view of the plate, showing the short denial island on the Halo plate, with the "full length" denial island on the T&S plate.

The Halo plate exhibited some deep pitting and active rust when I received it from the FFL. The Halo plate is clearly listed on the Halo web site as having holes spot drilled, rather than fully drilled for some of the rivet holes. Obviously, the Halo plate is NOT spot drilled. Additionally, the holes that are drilled are not countersunk for the rivet heads.

The T&S plate has all the holes drilled and countersunk for GI spec rivets, as they should be. Of note, I found the holes to be slightly undersized, allowing the builder to ream to finish dimension for the best possible fit.

It is very slightly visible in this photo - the T&S plate exhibits a darkened line forward of the back plate slot. T&S manufacturing has taken the additional step of heat treating the rear inch of the side plate to meet USGI specifications. This is a very nice touch for both durability and aesthetics on the finished gun.

|

|

|

Forward half of the right side plate.

The front right cartridge stop hole has been spot drilled on the Halo plate. This is the ONLY spot drilled hole that there is on the plate. The lack of chamfers is also obvious.

The T&S plate has an additional hole, visible on the denial island. This hole is an optional hole for the "early war" safety bar rivet. T&S was nice enough to locate, drill and thread this hole for me at no cost.

|

|

|

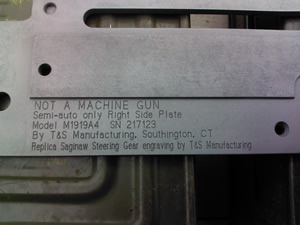

Both manufacturers mark their plates on the inside with their maker info, serial number and other pertinent info. I like the fact that this is on the inside of the plate - which is kosher per regs - allowing the outsides to have replica "original style" markings.

|

|

|

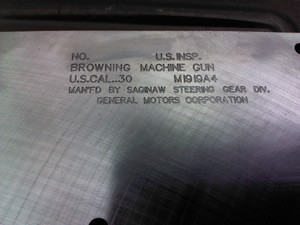

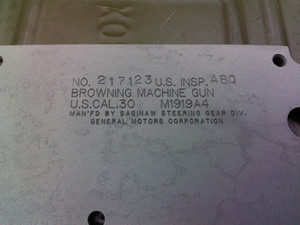

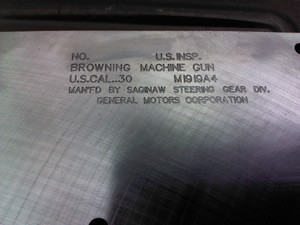

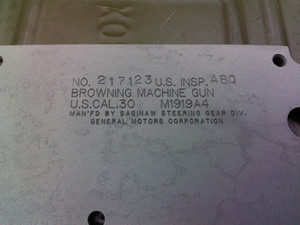

While on the subject of markings - here is the outside / replica markings.

The Halo plate does not have a serial number stamped on the outside of the plate. I'm not quite sure what to think about this. There is a serial on the inside... I'm not sure if I should be happy that I have the option to chose how the outside will be marked... or if I should be concerned. My initial reaction was disappointment.

The T&S plate has the serial number applied, as well as period correct inspectors markings. T&S will apply a crossed cannons stamp, unless otherwise requested. I requested to not have the crossed cannons stamp applied, as I would like to apply it myself after completion.

The serial number stamping on the T&S "walk" a bit up and down. I specifically asked for this to mimick the appearance of many original Saginaw production side plates. T&S was more than agreeable to fulfill my request.

Between the two, I prefer the T&S engraving in style and finish. |

Assembly:

Both plates are functionally "flat". Some semi auto side plates have been warped by poor procedure / attention during the milling operations.

The T&S plates are ready to start riveting straight out of the box.

The T&S plate has been fully deburred, then media blasted.

The Halo plates needs 9 holes located and drilled. 18 holes need countersunk / fitted to the rivets to be used.

The Halo plate appears to have been only quickly deburred. The inside of the plate was sandblasted. I question if the inside of the plate was blasted in an attempt to kill significant active rust.

The Halo plate takes some more time to finish to get into a position where it is ready for assembly. This isn't a terrible job to do, and can be done by a home hobbyist that doesn't have a machine shop - but for best results, the holes should be located and drilled on a vertical mill. Countersinks can be done on the mill or a drill press.

Conclusion:

Its clear to me that the T&S plate is the more complete product. At $50 more, I believe it is a good value and worth spending the extra money on based on completeness as well as the merits of detail.

The Halo plate appears to be of good quality - but suffers in comparison to the T&S plate due to being incomplete and lacking the finishing details.

Arguments could be made of the merits of the Halo plate being incomplete . Leaving holes not drilled allows the end user to "drill to match the parts kit", or complete details as the user sees fit.

In my opinion, the right side plate should be made to GI spec. Holes should be located and completely drilled per the print. If the other parts don't fit, they are out of spec and should be replaced - or the person doing the assembly should examine the method and process used to assemble the receiver box.

Illustrating my point, I've found that bottom plates can be particularly interesting, being warped and bent in interesting ways. Rather than allow the warped part to dictate the location and placement of holes in the right side plate - and thus the overall shape and potential squareness of the receiver box - do the right side plate correctly and adjust the bottom plate to fit properly.

Both plates are, or can be made serviceable - and are considered to be the superior plates on the market currently. I hope that this review has illustrated exactly what you get for your money and provide you the information you need to make a decision on purchasing the plate that best fits your requirements.

|