81mm Shell, M56

This article is from TM 9-1904 which is available on this site.

The contents have been supplemented with modern photos and comments or additional information added in some instances.

Date Compiled: 7/17/2007

Editor: Chris Guska

SHELL, H.E., M56. This shell was developed to replace the H.E. Shell M45 and is standard for issue and manufacture (S & M). It is used against dugouts, barricades, and underground structures where a mining action is desired. This shell is a much more effective one than the M45 due to the fact that it contains approximately 40 percent explosive filler as compared to 30 percent explosive filler of the M45. The greater the percentage of explosive filler, without sacrificing the penetrating ability of the shell body, the more effective is the shell when used for mining effect.

The shell body is constructed of forged steel. It is long and cylindrical in shape with a tapered nose and tail. It has a bourrelet machined on the body near the base of the shell which acts as a rear bearing surface and a gas check.

There are three raised portions around the shell near the nose to act as a forward bearing surface. The nose is machined and threaded to receive an adapter. The adapter is threaded to receive a fuse well cup and fuse. The fuse used is the M53 P.D. which has a delay in action on impact. For mining effect, penetration of the target produces the most effective results. The use of a delay action fuse, therefore, to allow penetration is mandatory. For details of functioning of the M53 P.D. Fuse, see page 300 to 303.

The base of the shell is closed, machined, and threaded to receive the stabilizer assembly. The shell filler consists of 4.31 pounds TNT. The weight of the completely assembled round is 10.77 pounds. The entire length of the shell with fuse assembled is 22.89 inches.

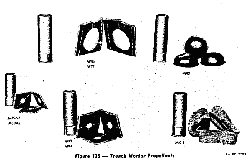

The fin assembly consists of a long stem and cartridge container made of aluminum alloy. Having stationary fins formed at the open end of the cartridge container, the stem is closed and threaded so as to be screwed to the shell body. The cartridge container which is part of the same unit is hollow, machined, and threaded at the open end to receive the percussion primer. There are holes in the cartridge container near the fins so as to conduct the flames from the ignition cartridge to the propellant increments which fit around the cartridge container.

The ignition cartridge. The earlier shell of this model used the M3 Ignition Cartridge red.

The later shell of the same model had the fin assembly threaded so as to receive the M6 Ignition Cartridge and percussion primer.

The Percussion Primer M34 is of the same construction and shape as the M33 previously described except that it has a greater diameter.

The Propellant Increment M2 is made up of thin square sheets of double base powder sewn together. A hole of the same diameter as the stem of the fin assembly is cut in the center of the increment and a slit runs to the outer edge so that the increments can be easily attached to the stem or removed to adjust the propelling charge.

In the latest manufacture, however, the increments are held in place by a star shaped spring wire clip known as a propellant holder. Each increment has 205 grains of double base powder.

The percussion primer, ignition cartridge, and four increments comprise the field propelling charge; a total of 940 grains of powder.

Zone of fire and range. The shell has five zones of fire. The first zone of fire consists of the ignition cartridge and percussion primer; zone five consists of the ignition cartridge, percussion primer, and four propellant increments.

Zone one has a range of approximately 300 yards.

Zone five has a range of approximately 2,655 yards.Marking and packing. The shell body is painted olive drab with yellow stencil. It is packed one per fiber container, three fiber containers per bundle, and one bundle per wooden crate for overseas shipment. The rounds are completely assembled ready for fire.

M56 Shrapnel

90th IDPG Weapons