Launcher, M1 for the M1903 Springfield Rifle: Variants and Details.

Date: April 2009

Author: Chris Guska

Research Assistant and Photographer: P.W. Browning

Special Thanks to: A. Winfrey and Rob

Background:

This article is a followup to the Reproduction M1 Launcher page here on 90thidpg.us

While conducting research on the M1 launcher for the 1903 Springfield rifle prior to starting on my reproductions I came across several variations in the M1 launcher. There are two variations in clamp assemblies and three variations in manufacturer’s markings. Additionally, original examples will exhibit both Black Oxide (Blued) and Zinc Phosphate (Parkerized) finishes.

The launchers contained herein are from the A. Winfrey collection, photographed by P.W. Browning except where noted.

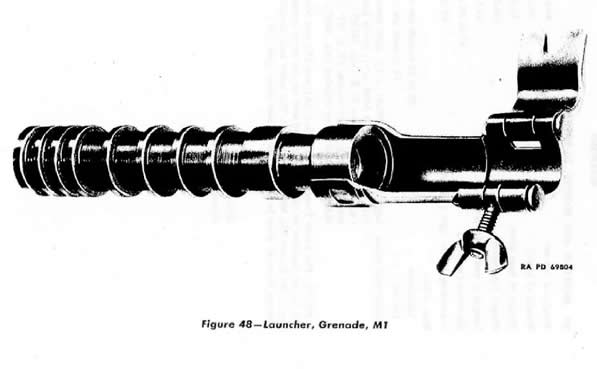

The Basics:

Variations:

The variations within the launcher are interesting notes within the short production and service history of these launchers. The M1 launcher was adopted December 30, 1940 and first manufactured by the Knapp Monarch Company, the main contract holder, in November 1941. By the time that production of the M1 launcher ceased in May 1943, almost 323,000 launchers had been manufactured. An additional 100,000 M2 launchers for the M1917 rifle had been produced concurrently, with 40,000 of those being converted for use with the M1903 Springfield rifle.

There are four main points of variances between the launcher types:

1.) Clamp Construction

2.) Tube Face

3.) Marking Variants

4.) Finish Type

1.) Clamp Construction

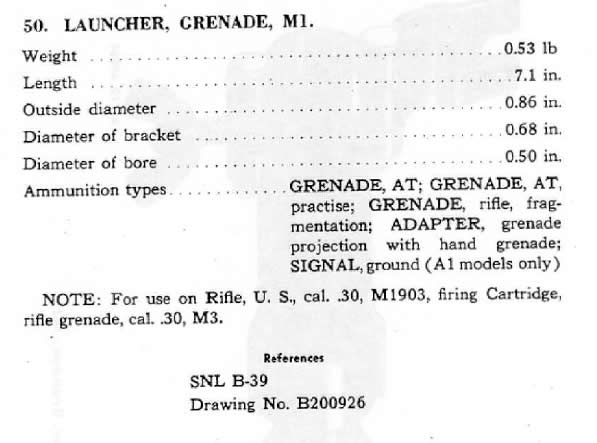

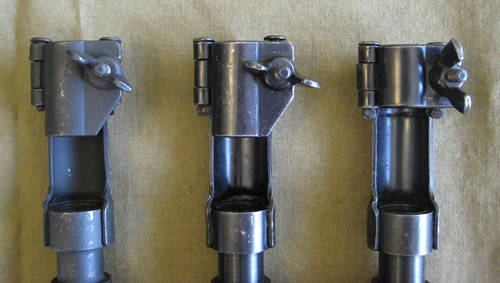

There are essentially two different types of clamp “doors” observed on original launchers. The first, and “early” pattern is a short door as originally designed and produce, while the second and “late” pattern has the door extended to prevent the launcher from moving in relation to the front sight.

“Short” PatternNotice how there is a gap between the rear edge of the front sight base and the front edge of the launcher door.

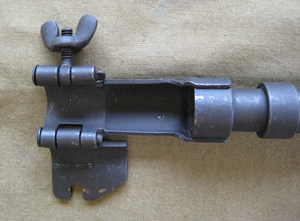

This gap could potentially allow the launcher to slide forward allowing a gap between the muzzle and launcher to open releasing some of the propellant gasses. In July 1942, the door was redesigned and simply extended such that the rear edge of the front sight base would be very close, or in contact with the front edge of the door when the launcher was affixed. This effectively eliminated the issue of the launcher creeping forward and allowing gasses to escape between the muzzle and the device.

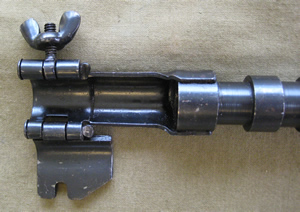

All launchers produced from July of 1942 had the longer type door assembly. The army also issued Field Service Work Order B39-W1 for all existing stocks of launchers with the early short style door be fitted with the new extended door assembly. Launchers that were converted from short door to long door configuration were phosphated at the time of conversion."Modified" Pattern

"Long Door" PatternThe launchers as produced from Knapp Monarch as long door types were finished with a black oxide (hot blued) finish over the freshly machined or stamped surface just as the short door types had previously been.

2.) Tube Face

Related to the "Short Door" vs "Long Door" types is a difference in the face / muzzle of the launcher.The first pattern short door pattern launchers will exhibit a stepped / flat face at the muzzle, while the second pattern launchers will have a chamfer on the outside radius at the muzzle.

Stepped / Flat Face 1st Pattern Chamfered 2nd Pattern Launchers that were modified from the short door to the long door after July , 1942 will have a chamfered muzzle and have a phosphate finish from their arsenal rework.

3.) Marking Variants

During the course of my research, I observed three different marking variations on the launchers.

1.) Nomenclature only, no makers mark or logo on the body or door.

2.) Nomenclature and K&M logo on the body.Modified 1st Pattern to Long Door

2nd Pattern / Long Door

3.) No nomenclature on the body and small makers mark on the door.

4.) Comparison of the 90th IDPG Reproductions to Original markings

4.) Finish Types

Of the original examples, most retain their original Black Oxide (blued) finish while others have a Zinc Phosphate finish. As originally produced, the launchers received a Black Oxide finish over the degreased machining and stamping. The launchers were not a bright finish/polished blue, but a medium to semi-bright finish from the fresh machining and stamping. Some launchers were arsenal re-finished with a Zinc Phosphate finish, but will be in the minority of surviving examples.

Of note are the M2 launchers produced for the M1917 rifle: Approximately 40,000 M2 Launchers were converted for use on the M1903 rifle by boring out the tube of the launcher to fit the larger M1903 muzzle and overstamping the M1917 with M1903. During the conversion process, these M2, now M1 launchers received a Zinc Phosphate finish.

Conclusion:

All variants of the M1 launcher would have seen service in the ETO, undoubtedly remaining in service until the end of hostilities. Even with the introduction and concurrent use of the M7 and M8 launchers, the M1 proved itself to be a highly effective, reliable solution for providing the infantry with greater firepower.

For more reading on the M1 launcher and US WWII Rifle Grenades in general, I highly recommend that you check out

- Popernack Collectables page on US Grenade Launchers

- Bill Ricca's page on US Grenade Launcher

- Inert-Ord.net Grenade Launcher info

For information regarding the 90th IDPG Reproduction M1 launchers for the 1903 Springfield Rifle

Sources

Brophy, William S. The Springfield 1903 Rifles. New York: Stackpole Books, 1985.

Campbell, Clark S. The '03 Springfield Rifles' Era. New York: Campbell Books, 2003.

Canfield, Bruce N. U. S. Infantry Weapons of World War II. New York: Andrew Mowbray Incorporated,, 1996

United States. War Department. TM 9-2200 Small Arms, Light Field Mortars and 20-mm Aircraft Gun, 11 October 1943

90th IDPG Weapons