Israeli soldier on guard at the destroyed railroad bridge at El Quantarah, 1967, Rene Burri/Magnum Photos

|

Introduction

The Browning 30 Caliber machine gun had a long service life spanning well over half a century serving in many nations. The weapons system evolved from a water cooled heavy machine gun to be a multi role infantry, armor and aerial weapons platform. Because of its evolution and substantial production, there are many interesting parts variants and accessories that are available to us as a collectors and reenactors.

The Israeli military made use of and made significant modifications to the 1919A4. A substantial quantity Israeli 1919A4's were returned to the US in the form of parts kits for commercial sale since the late 1990's. These are the dominant examples in use with reenactors and on display at most events.

There are visible and obvious differences between Israeli modified 1919A4's and USGI 1919A4's. The purpose of this article is to illustrate those differences on a component basis.

Booster:

There were 2 types of boosters utilized during WW2 on 1919A4 Browning 30 Cals. On the right is the "early" style 2 piece booster assembly consisting of a bearing with fore and aft lock rings, and a threaded in booster plug. This style saw service throughout WW2, with a change to the single piece, straight wall combined bearing and booster evidenced in combat photos as early as the siege of Metz. Both types of booster saw service in the ETO.

Due to pressure differences between 30.06 and .308, the Israelis sleeved down original USGI boosters from a .718 diameter booster aperture to .531 (13.5mm) for increased back pressure and reliable function. Additionally, these modified boosters were marked as illustrated below.

The two piece boosters can be easily brought back to USGI configuration by removing the threaded booster plug, retaining the bearing, and replacing the booster plug with a USGI .718 dia part.

|

Front & Rear Sight:

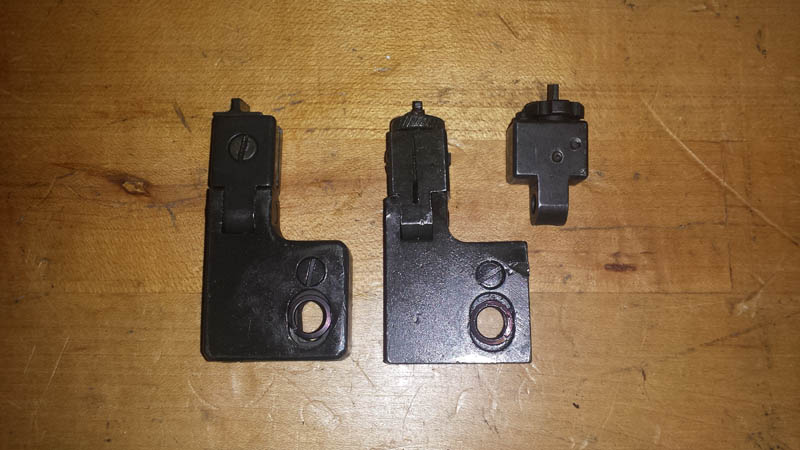

This photo shows a progression of front sights, from a left to right adjustable dovetail, to a threaded elevation adjustable sight, to a click adjustable elevation site much like we are used to on AR15's.

The Israeli military did not come up with or modify the front sight, but appears to have just used the parts that were supplied with their kits, or upgraded to more current styles with spare parts out of inventory.

The left sight, with dovetailed windage adjustment is the WW2 type. The screw and click elevation adjustment sights were used post WW2.

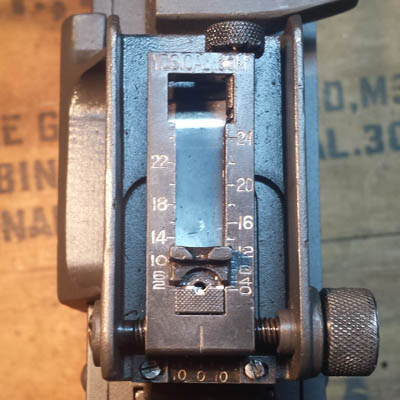

Rear sights were substantially altered, with the USGI sight graduations being removed and new graduations applied for the 7.62 caliber. Original USGI sight leaves were used, so remnants of markings at the top and rear are usually apparent.

Used USGI 30.06 sight leaves are available for sale from numerous commercial parts suppliers, and are easily replaced with a pin punch and screw driver by removing the windage knob and screw.

Additionally, a protective tab was welded to the front of the rear sight bracket to protect the elevation screw.

This can be removed with a dremel and careful file work to return to USGI configuration as illustrated at right.

|

Trunion:

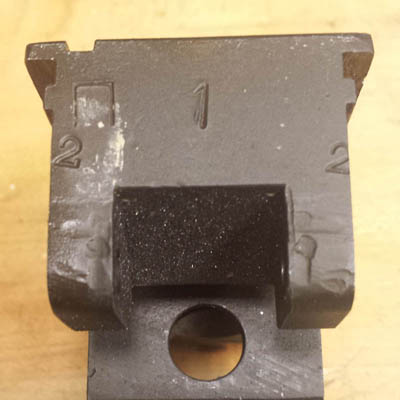

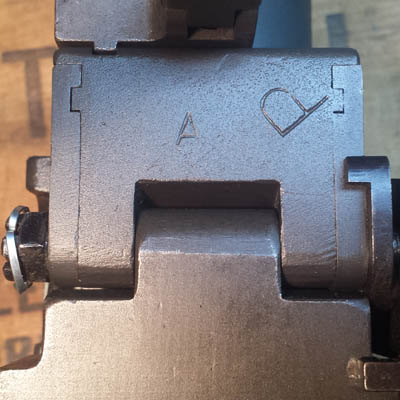

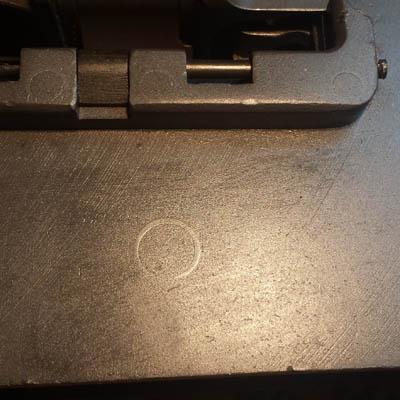

Occasionally, but not always, trunions seeing IDF service were marked with the "n" character.

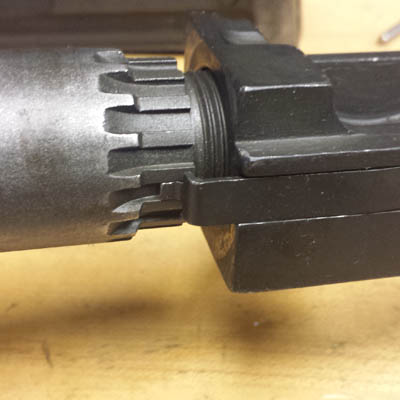

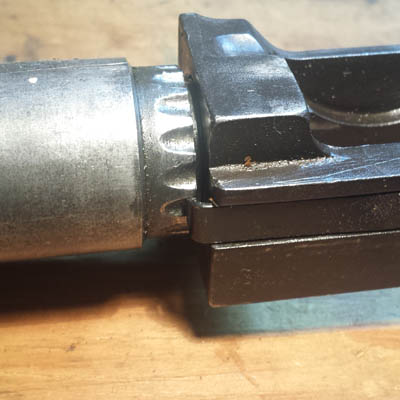

The primary modification to the trunion was a slot milled for the widened belt holding pawl. This is evidenced by the round radiused cut as illustrated at lower left.

This radiused cut can be welded up and the area re-machined to restore it back to USGI configuration, beyond the facilities of most hobbyists.

|

Right Rear Cartridge Stop:

Changing from 30.06 to .308 caused challenges in reliable feeding because the .308 round is shorter. The relative position of the belt or link in the feed way and where it exits the right side is changed. The back of the belt or link sits about 1/4 inch further to the rear of the gun than it does on a 30.06 example which causes the belts or links to jam on ejection.

This necessitated shortening the 30.06 right rear cartridge stop as illustrated at left, to increase the "window" on right side plate for clear, unobstructed ejection of the belt or link.

The israeli's went with the most minimal, least obtrusive, while yet still functional right rear cartridge stop.

This part is riveted into the gun and typically cant be changed without significant work. That being said, for the purposes of running blanks or shooting just about anything - it is preferable to utilize the Israeli .308 rear stop for functionality purposes. When building 1919A4's for reenacting, I personally recommend installing the .308 rear stop, OR threading the rivet hole and carefully face welding over and filing flush, so that the right rear stop can be changed from 30.06 for display, to .308 for action.

|

Belt Holding Pawl & Bracket:

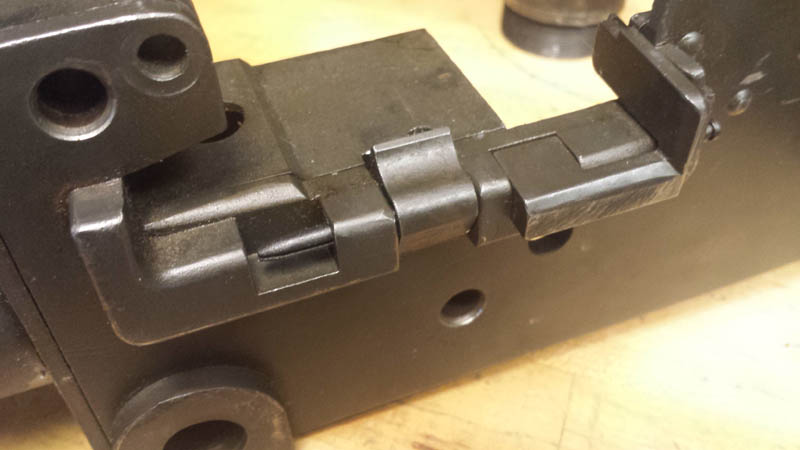

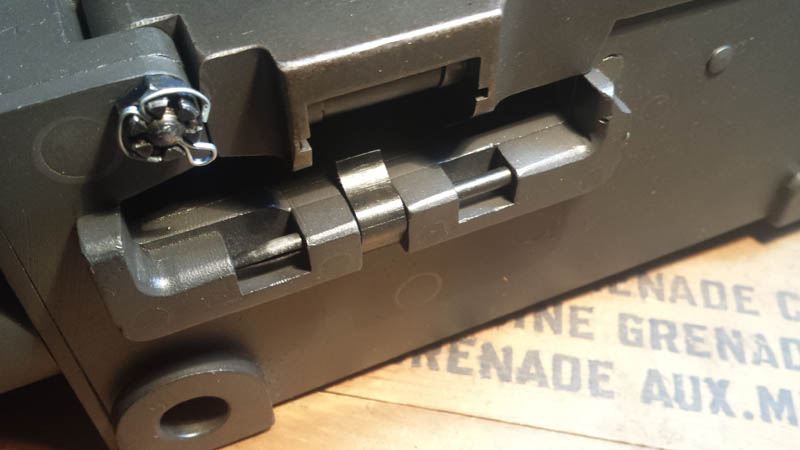

illustrated immediately below is the widened Israeli belt holding pawl and modified belt holding pawl bracket.

This modification is once again due to the relative position of the .308 ammunition in the feedway, for reliability of feeding and function with links. The Belt holding pawl bracket was machined wider, a slot made in the trunion for clearance as previously discussed, and an entirely new made belt holding pawl installed.

|

Topcover:

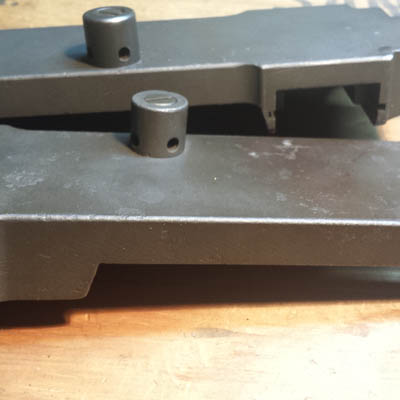

Illustrated below are a late cast type (top), and early milled type (bottom) top cover assembly, as from Israeli service. Both are "n" marked as almost all topcovers from IDF service are. The bottom part has a radius cut at the front for clearance of the front sight post - this was a late (post WW2) USGI modification that was also occasionally evidenced on Israeli examples.

The IDF modified the belt feed pawl and slide, once again due to the relative position of the shorter 7.62 cartridge in the feed way for reliability when feeding links. The pawl arm was bent down slightly and the slide machined for clearance of the modified arm, illustrated bottom left.

Additionally, to resolve the issue of worn belt feed lever pivot pins and feed arm holes, the Israelis modified most all top covers and feed arms to a superior bottom up design, with a countersunk pin inserted up through the feed arm being captured by a cotter pin at top. This design utilized a set screw in the pivot bushing to take up any slop. It is without a doubt a superior design and implementation than the USGI approach, but is entirely wrong for WW2, this was never done by the US military.

Some of the parts can be salvaged off of Israeli topcovers, specifically the pivot bushing, extractor spring, pawl spring and pin. The balance of the parts should be replaced with GI, typically at a cost of around $75 or less.

Most Israeli topcovers have serial numbers stamped on them. To the best of our research, this was not applied by the US military, but by the Israelis themselves.

|

Bolt:

Due to the differences, albeit slight, between the 7.62 and 30.06 case head, the IDF modified the T slot on the face of the bolt slightly larger for reliable free passage of the case head. These bolts were marked on top 7.62 in various fonts. USGI unmodified bolts lack this marking.

Since the 7.62 marking is not correct for a WW2 presentation, the marking can be filled with weld and draw filed to effectively "erase" the mark. For practicality purposes and actual use, I highly recommend the use of 7.62 marked Israeli bolts, as they will reliably feed 30.06, 8mm, 7.62 and a number of other calibers.

I personally use an Israeli modified bolt with the markings erased.

Illustrated at bottom are a line up of bolt handles - from left to right:

Extended Charging Handle - Not a WW2 issue item for 1919A4's,

Slotted Belled Charging Handle - Israeli modified WW2 production

Belled Charging Handle with takedown pin - WW2 production

Belled Charging Handle without takedown pin - Early WW2 production

(Not illustrated) Straight charging handle - Late WW2 production

|

Barrel & Barrel Extension:

Illustrated at left is an Israeli 7.62 barrel, identified by its square barrel lock spring cuts. USGI illustrated at right with round notches.

The IDF changed the barrel lock spring and barrel notch design to provide a very secure method eliminating any chance of the barrel "walking" headspace through use. It makes adjusting headspace a pain in the ass (in my opinion) as it requires a tool be used to hold the spring out while the barrel is adjusted. This design is entirely of Israeli origin.

I recommend utilizing a USGI barrel locking spring for ease of headspace adjustment, they typically are under $5.

|

Lockframe:

On lockframes that saw IDF service, a flat was machined on the trigger bar stop, with a screw and capture nut installed. This modification was for easy adjustment of timing. The full auto Browning 30 Caliber has advanced ignition, such that the firing pin begins to drop before the barrel and lockframe are in their fully forward position.

Originally, the trigger was to be "adjusted" by bending it to achieve the desired timing. The IDF simplified this by adding this screw.

This screw and nut combination were later used as a convenient place for a trigger return spring on semi automatic civilian conversions.

|

Conclusion:

There are a number of internal and external differences between truly original "USGI" 1919A4's as they were in US Service, and those that saw IDF service.

Fortunately, parts for the 1919A4, both Israeli and original USGI configuration are still plentiful and available at reasonable prices. Should the desire be there to upgrade, or restore the 1919A4 back to WW2 USGI configuration, everything is available and there are gunsmiths who can do this work.

Furthermore, for reenacting purposes and practicality, guns can be outwardly configured to appear as USGI, but can be made to very successfully run .308 or calibers other than 30.06 for affordability.

I hope this article sparks some interest to go back and revisit the 1919A4's currently in use and learn more about their history and the components they are made of. |